Projects

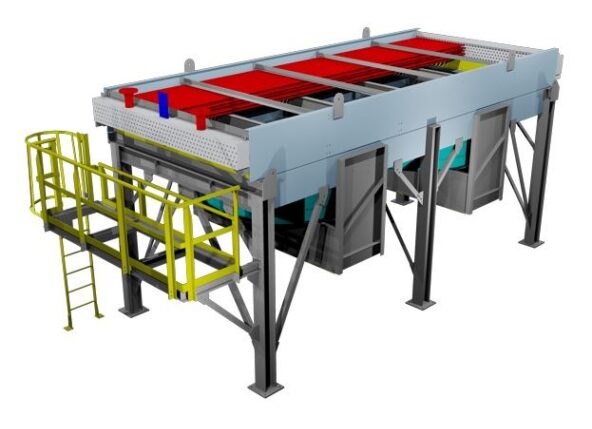

Design and Supply Crude Oil Cooler for Mobile Cepu Ltd

ID PROJECT: | |

|---|---|

CUSTOMER: | |

PROJECT TITLE: | Design and Supply Crude Oil Cooler for Mobile Cepu Ltd |

TYPE: | |

EQUIPMENT NAME: | |

SCOPE OF WORK: | |

WEIGHT KGS: | |

YEAR BUILT: | |

CODE/STD: | |

NOTES : |

Specification Summary

Code Compliance

We did

Safety summary

For any project inquiries, feel free to contact us